Dust Collector Bags and Cages: A Comprehensive Buying Guide

Imagine a clean, dust-free environment in a bustling construction site. What would you choose to protect your workers? Dust collector bags and cages are your answer. Available in a variety of sizes, colors, and materials, these essential components are not just tools for cleaning; they're partners in maintaining hygiene and productivity. Whether you're managing particulate matter in a factory or keeping your workshop pristine, the right bag and cage system can make a world of difference.

Why Dust Collector Bags and Cages Matter

Dust collector bags and cages are vital because they help in maintaining a clean and safe working environment. This is not just about aesthetics; its about safety, regulatory compliance, and productivity. These components are designed to prevent dust and particulate matter from escaping into the air, ensuring a healthier and more efficient workspace.

Understanding the Types of Dust Collector Bags and Cages

There are several types of dust collector bags and cages, each with its own advantages and applications. Lets dive into the details to help you make an informed choice.

Fabric Bags

Fabric bags are the most common type, made from materials like cotton, polypropylene, or non-woven fibers. They offer a good balance between cost and performance.

- Cotton Bags: Soft and easy to clean, ideal for applications where hygiene is a concern.

- Polypropylene Bags: Strong and durable, suitable for heavy-duty applications.

- Non-woven Bags: Highly effective at trapping dust particles and ideal for industrial settings.

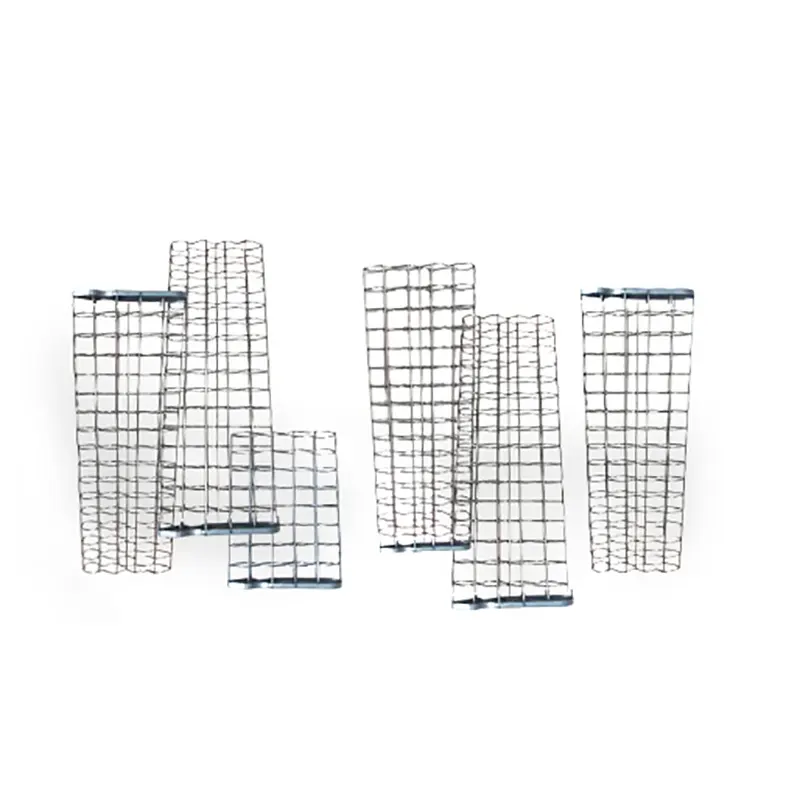

Metal Cages

Metal cages, typically made from steel, stainless steel, or carbon steel, are known for their strength and durability.

- Stainless Steel Cages: Highly resistant to rust and corrosion, ideal for outdoor or corrosive environments.

- Carbon Steel Cages: Affordable but may be less durable than stainless steel options.

- Galvanized Steel Cages: Offer protection against rust and corrosion, suitable for industrial applications.

Hybrid Systems

Hybrid systems combine fabric bags with metal cages to create a robust and flexible solution.

- Polypropylene Bags with Metal Cages: Balances cost-effectiveness and durability.

- Non-woven Bags with Metal Cages: Ideal for heavy-duty applications, offering both strength and reliability.

Factors to Consider When Selecting Dust Collector Bags and Cages

When choosing the right dust collector bags and cages, consider the following key factors:

Filtration Efficiency

- Efficient Filtration: Ideal for applications where precise control over dust levels is required.

- Manageable Filtration: Suitable for less demanding applications, like construction or automotive industries.

Durability

- Impact of Material: High-quality materials like non-woven fibers and stainless steel provide better durability and reliability.

- Maintenance-Free Components: Rust-resistant materials, such as stainless steel, offer longer-lasting solutions.

System Compatibility

- Size and Shape: The dimensions of the bags and cages should match the collection system to ensure optimal performance.

- Ease of Installation: Components should be easy to install and remove for regular cleaning and maintenance.

Maintenance Requirements

- Regular Cleaning: Remove dust particles regularly to prevent mold or bacteria growth.

- Inspection: Check for signs of wear or damage and address them promptly.

- Replacement: Worn-out components should be replaced to maintain the systems efficiency.

Material Options and Their Impact on Performance

The choice of material directly affects the performance and durability of dust collector bags and cages.

- Fabric Bags: High-quality materials like non-woven fibers provide better durability and efficiency.

- Metal Cages: Stainless steel and galvanized steel offer higher durability and resistance to environmental factors.

- Hybrid Systems: Balances cost-effectiveness and durability, making them suitable for various scales of operations.

Installation and Maintenance Tips for Dust Collector Bags and Cages

Proper installation and maintenance are crucial for optimal performance.

Installation Tips

- Proper Setup: Install the bags and cages at the correct height and angle to prevent dust from escaping.

- Tight Fittings: Use high-quality fasteners and sealants to ensure secure attachment.

- Access for Maintenance: Design the installation for easy access to clean and maintain the system.

Maintenance Tips

- Regular Cleaning: Remove dust particles regularly to prevent mold or bacteria growth.

- Inspection: Check for signs of wear or damage and address them promptly.

- Replacement: Replace worn-out components to maintain the systems efficiency.

Comparative Analysis of Dust Collector Bags and Cages

To choose the best dust collector bags and cages for your needs, consider factors like filtration efficiency, durability, system compatibility, and maintenance requirements.

Fabric bags are ideal for small to medium-scale operations, while metal cages are better for heavy-duty applications. Hybrid systems offer a balanced solution, making them suitable for various scales of operations.

Proper installation and maintenance are crucial for optimal performance. By selecting the right components and following best practices, you can ensure a clean, safe, and efficient work environment.

Summary and Call to Action

By understanding the different types of dust collector bags and cages and considering the key factors involved, you can make an informed decision that will enhance your work environment. Dont just choose based on cost; prioritize quality and reliability. Ready to take the next step? ()!

-

-

2.1Fabric Bags

-

2.2Metal Cages

-

-

-

3.2Durability

-

-