Finding the Best Dust Collector Filter Bags with Trusted Manufacturers

Understanding the Importance of Dust Collector Filter Bags

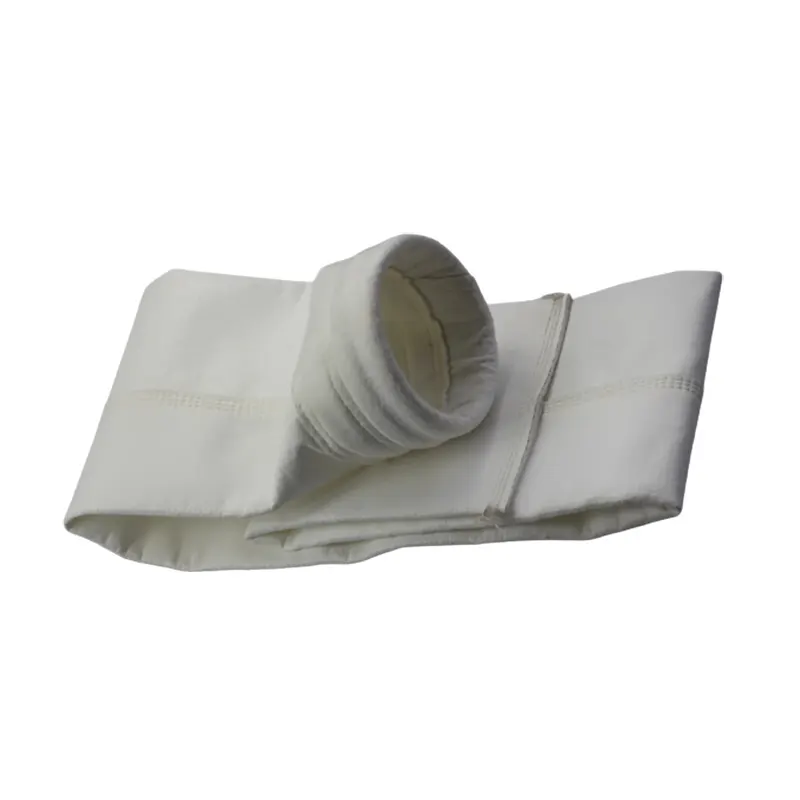

Filter Bag Types

Dust collector filter bags come in various types, each designed to meet specific needs. Common types include pulse-jet bags, cartridge filters, and fabric filters. Pulse-jet bags are ideal for applications where high filtration efficiency is required, while cartridge filters are better suited for capturing fine dust particles. Fabric filters, on the other hand, offer a cost-effective solution for capturing larger particles.

Performance Metrics

The performance of dust collector filter bags is determined by several metrics, including filtration efficiency, durability, and material resistance. High efficiency ensures that more particles are captured, reducing the amount of dust and debris released into the air. Durability ensures that the filter bags can withstand constant filtration without wearing out quickly. Material resistance, particularly to chemicals and temperatures, is crucial for maintaining performance in harsh environments.

Identifying Trained Manufacturers

Reputation and Credentials

When choosing a manufacturer, their reputation and credentials are paramount. Trusted manufacturers have a proven track record of delivering high-quality products and maintaining customer satisfaction. Look for manufacturers that have received certifications from reputable organizations such as UL, ISO, and CE. These certifications indicate that the manufacturer adheres to strict quality standards and meets international safety and environmental requirements.

Customer Support and After-Sales Service

A manufacturer's customer support and after-sales service play a critical role in ensuring that you receive the best possible experience. Reliable manufacturers offer comprehensive training, installation guidance, and prompt support for any issues that may arise. They should also provide warranties and regular maintenance schedules to keep your filter bags in optimal condition.

Key Considerations for Filtration Performance

Material Selection

The material of the filter bags is crucial for their performance and longevity. Manufacturers like Tyco Filtration and Filtration Solutions offer a wide range of materials, such as polyester, polypropylene, and polyvinyl chloride (PVC), each with unique properties. For example, polyester is excellent for dusty environments, while polypropylene is better for capturing fine particles.

Filtration Efficiency Testing

To ensure that the filter bags meet your specific needs, they should undergo rigorous testing to verify their filtration efficiency. Independent testing agencies can provide unbiased evaluations, ensuring that the bags perform as advertised. Testing includes parameters such as particle size distribution, dust load capacity, and pressure drop.

Real-World Applications and Case Studies

Industrial Applications

In industrial settings, such as manufacturing plants and construction sites, dust collector filter bags are essential for maintaining a clean and safe work environment. For instance, a construction company might use pulse-jet bags to capture fine dust particles generated during demolition and restoration work. The durability and efficiency of these bags are critical in ensuring compliance with local air quality regulations and protecting workers' health.

Environmental Impact

The environmental impact of filter bags is another important consideration. Sustainable manufacturers use eco-friendly materials and processes to minimize their carbon footprint. For example, a manufacturer using recycled materials or biodegradable options can significantly reduce the environmental impact of their products.

Conclusion

In conclusion, selecting the best dust collector filter bags requires careful consideration of their type, quality, and the manufacturer's credentials. By understanding the importance of these components, you can make an informed decision that aligns with your industrial needs. Trusted manufacturers offer high-quality, durable, and efficient filter bags that not only meet the immediate needs of your dust collection system but also ensure long-term returns in terms of cost savings, improved safety, and better environmental performance. Prioritizing quality and durability can ensure that your dust collector filter bags will serve you for years to come, providing reliable performance and peace of mind.

By making these adjustments, the article will become even more effective in guiding readers through the process of selecting the right dust collector filter bags.