Why Your Dust Collector Filter Cage Might Be Clogging and How to Fix It

Imagine stepping into your workshop, only to be greeted by an enveloping cloud of dust. No matter how advanced your dust collection system, a clogged filter cage can turn it into a nightmare. This frustrating scenario is all too common, and understanding the importance of a clean filter cage can make a world of difference.

A well-maintained dust collector filter cage is crucial for ensuring clean air, reducing respiratory issues, and maintaining optimal operational efficiency. In this guide, well walk you through the key aspects of dust collector filter cages, common causes of clogging, and strategies for both prevention and troubleshooting.

Understanding the Structure and Function of a Dust Collector Filter Cage

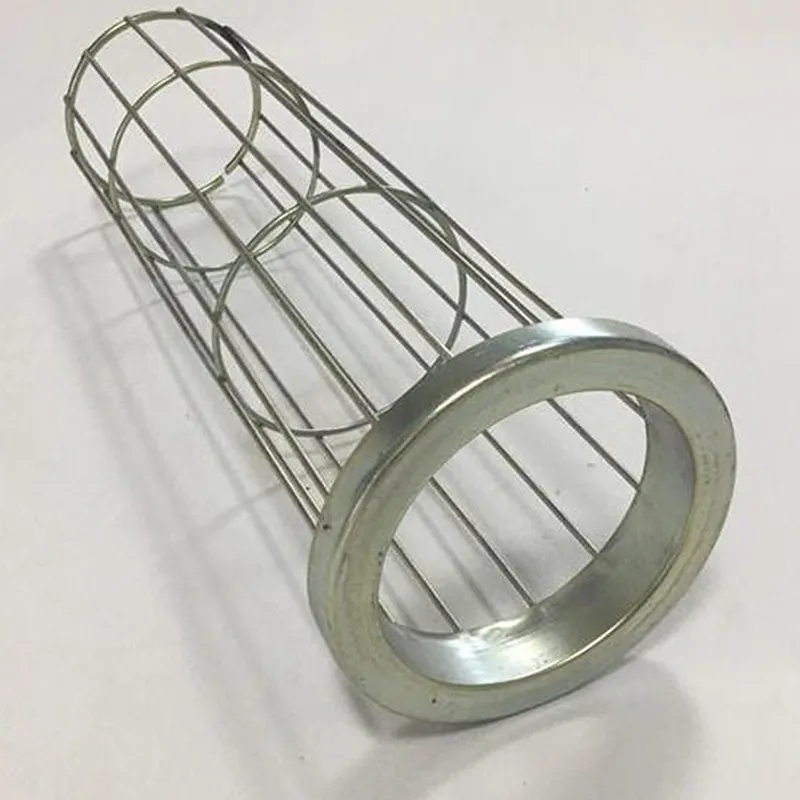

The filter cage is the heart of your dust collection system, intercepting and trapping dust particles as they pass through. Made from durable materials such as wire mesh, carbon fiber, and steel, the filter cage plays a vital role in maintaining air quality.

Structure of the Filter Cage

- Wire Mesh: With its fine weave, wire mesh is effective at capturing small dust particles, making it a common choice in many dust collector systems.

- Carbon Fiber: Known for high resistance to heat and wear, carbon fiber filters are ideal for industrial environments that demand durability and high performance.

- Steel: Robust and suitable for heavy loads and high temperatures, steel mesh or cages offer the strength needed in demanding applications.

How the Filter Cage Works

As dust enters the dust collector, it is forced through the filter cage. The air moves through the mesh, trapping the dust particles while allowing clean air to pass through. This barrier ensures that clean air exits the collector, while dust remains contained.

Heres a step-by-step breakdown:

1. Dust enters the dust collector.

2. Air flows through the filter cage.

3. Dust particles are intercepted and trapped by the mesh.

4. Clean air exits the collector.

Common Causes of Clogged Dust Collector Filter Cages

Clogged filter cages can be caused by several factors, and understanding these can help you take proactive steps to avoid clogging issues.

1. Dust Accumulation:

Over time, dust and debris can accumulate on the mesh, forming a physical barrier that restricts airflow and traps dust. Regular cleaning is essential to prevent this buildup.

2. Insufficient Maintenance:

Regular cleaning and maintenance are critical. If the filter cage is not cleaned regularly, it can become clogged with dust, debris, or even moisture, significantly reducing its performance.

3. Inadequate Airflow:

Restricted airflow can lead to pressure build-up, increasing energy consumption and promoting dust accumulation. Proper airflow management is crucial to maintaining optimal performance.

4. Improper Filter Material Selection:

Choosing the right filter material is essential. Materials that are prone to sticking or retaining moisture, such as those made with sticky or absorbent substances, can become clogged over time and reduce the filters effectiveness.

Identifying Clogged Dust Collector Filter Cages

Recognizing the signs of a clogged filter cage early can help you take swift action to prevent further issues.

1. Visual Inspection:

Regularly check the filter cage for visible signs of wear, dirt, or debris. A clogged filter cage will show visible dust or debris on the mesh or within the filter media.

2. Performance Metrics:

Monitor the performance of your dust collector. Increased power consumption, decreased airflow, and higher dust levels can signal a clogged filter cage.

3. Pressure Drop:

A significant pressure drop across the filter cage indicates potential clogging. Pressure drop is the difference in pressure before and after the filter cage and is a key indicator of performance. A drop in pressure often means the filter is not functioning optimally.

Preventive Maintenance and Tips for Keeping Your Dust Collector Filter Cage Clean

Regular maintenance is the key to preventing clogged filter cages and ensuring optimal performance.

1. Regular Cleaning:

Clean the filter cage regularly using compressed air or wet cleaning methods. Proper cleaning ensures that the filter cage remains effective. Here are some techniques:

- Compressed Air: Effective for blowing out loose debris.

- Soft Brushes: Useful for scrubbing away stubborn dirt.

- Chemical Cleaners: For particularly stubborn clogs (always follow manufacturer instructions).

2. Proper Filter Media Selection:

Choose filter media that efficiently traps dust particles and has high dust retention capacity. Common choices include:

- HEPA Filters: Ideal for capturing very fine particles.

- Spiral Filters: More durable and suitable for heavy-duty applications.

- Fiberglass Filters: Cost-effective and suitable for general use.

3. Airflow Management:

Proper airflow management is crucial. Adjust valves, use pressure regulators, and ensure proper fan sizing for optimal performance. Here are some tips:

- Regularly check valves and airflows to ensure they are properly adjusted.

- Use pressure gauges to monitor system pressure and identify potential issues.

4. Monitoring and Recording:

Implement a monitoring system to track filter cage performance. Record data such as pressure drops, airflow rates, and filter performance. This can help identify potential issues and ensure that your system is operating as it should.

Troubleshooting Clogged Dust Collector Filter Cages

When you suspect a clogged filter cage, heres what you can do:

1. Immediate Action:

If you suspect a clogged filter cage, take immediate action by bypassing the filter or increasing cleaning frequency. This can resolve minor issues and maintain system performance.

2. Detailed Cleaning Routine:

Use the appropriate cleaning agents and tools:

- Compressed Air: Effective for blowing out loose debris.

- Soft Brushes: Useful for scrubbing away stubborn dirt.

- Chemical Cleaners: For particularly stubborn clogs.

3. Preventing Future Clogs:

Implement long-term solutions to reduce dust accumulation and extend filter cage lifespan:

- Improving Filter Design: Use modern, efficient filter designs that are less prone to clogging.

- Using Filter Housing Modifications: Install features that help prevent dust buildup and promote better airflow.

- Enhancing Maintenance Schedules: Increase the frequency of cleaning and maintenance to catch issues early.

Ensuring Optimal Dust Collector Performance

Maintaining a clean and well-maintained dust collector filter cage is essential for optimal performance. By understanding the common causes of clogging, identifying clogs through visual inspection and performance metrics, and implementing preventive maintenance and cleaning strategies, you can ensure your filter cage remains effective and clean.

Regular maintenance not only prevents clogging but also extends the filter cages lifespan and ensures efficient dust collection. Adopting these practices will help integrate effective maintenance into your daily operations, ensuring your dust collector operates at its best.

Whether youre a small shop owner or a large industrial operation, keeping your dust collector's filter cage clean is critical for maintaining a safe and productive work environment. Take the time to implement these strategies and watch your dust collector perform at its best.