Latest Large Dust Collector Bags Large Dust Collector Bags Company

Product details of the large dust collector bags

Quick Overview

The material and design of SFFILTECH large dust collector bags will withstand the rigors of the intended use. The quality of this product is one of the best due to the adoption of the strict quality control system. SFFILTECH's large dust collector bags can be used in multiple industries and fields. SHANGHAI SFFILTECH CO., LTD has a knowledgeable talent team and a stable and reliable production line.

Product Information

large dust collector bags's details are presented below. They help better know the product.

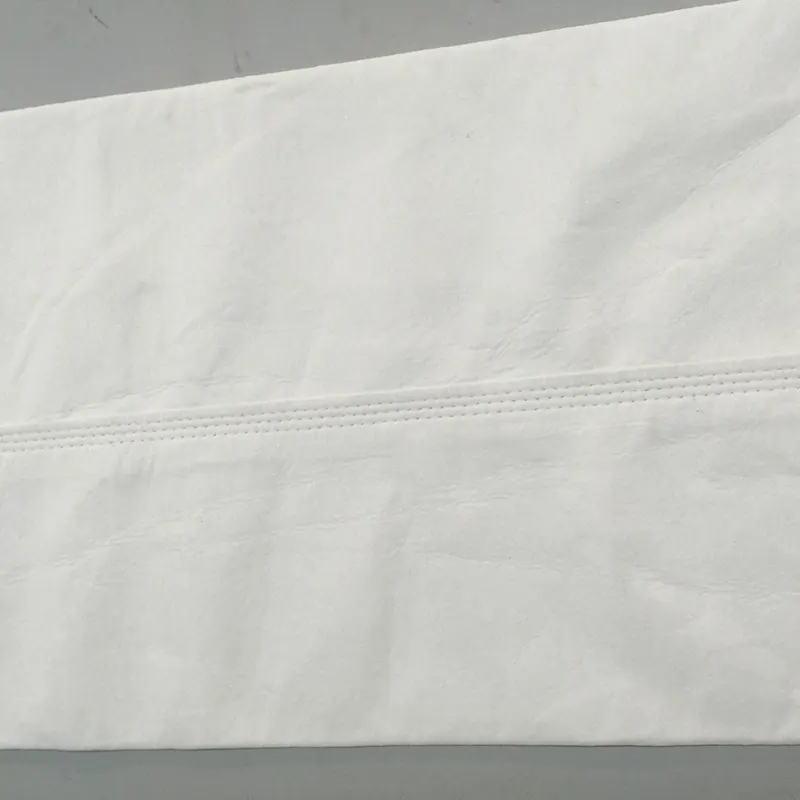

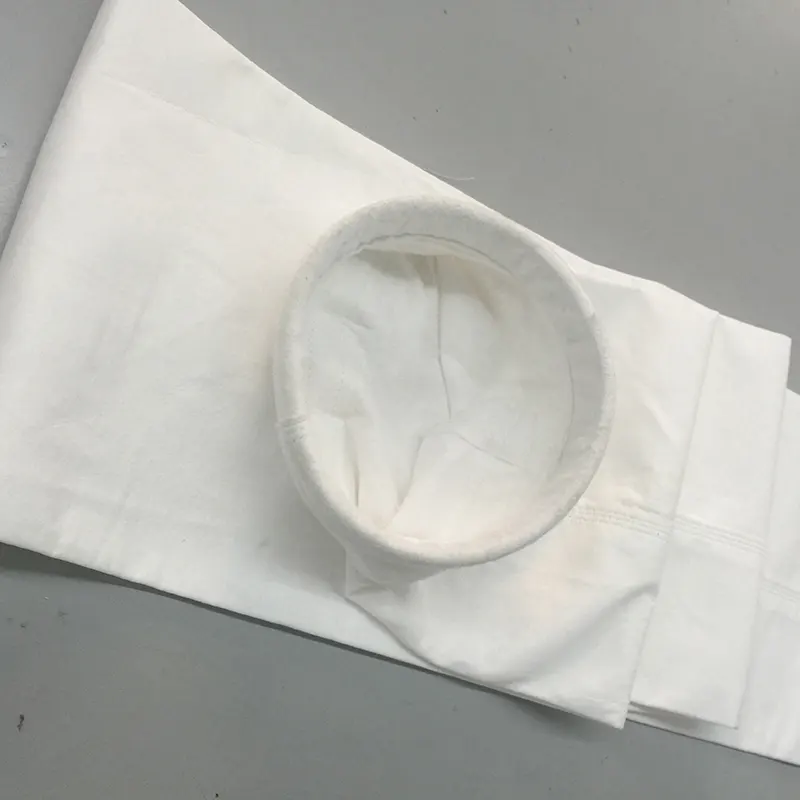

Sffiltech high temperature pure PTFE dust filter bag

Embark on a journey of advanced filtration with our PTFE filter bag solutions. Crafted from resilient PTFE fibers, these high-performance filter bags excel in high-temperature applications, ensuring efficiency in the most demanding environments. Characterized by chemical inertness, PTFE bags offer unparalleled resistance to various chemicals. Elevate your filtration system with PTFE membrane filter bags, designed to enhance filtration efficiency. Our industrial PTFE filtration solutions, including custom and micron-level options, cater to diverse needs. From dust collector bags to chemical-resistant fiber bags, our PTFE offerings stand as a testament to reliability and versatility. Experience the innovation of PTFE anti-static bags, ensuring safety in industrial environments. Explore the efficiency of PTFE filtration, backed by the exceptional performance of our PTFE filter bags. Unleash the full potential of your filtration system with our PTFE bag solutions.

Two factors effect the choice of filter bags

Dust Separation Procedure

Different dust separation procedures require different weights and air permeability values for filter media.

Rules:

- The more effective the cleaning process, the more compact and heavier the filter medium can be.

- The higher the emission control standards, the heavier the filter medium should be.

Tops: If these factors are well considered in advance, running cost like electricity for the fan or pressured-air for the cleaning pulses can be saved later on in a great amount.

|

Dust Separation Procedure |

(g/m2) Weight |

Air Permeability |

|

|

mm/s @200Pa |

l/(dm²min) @200Pa |

||

|

Intermittent Shaking |

300-350 |

667-1000 |

400-600 |

|

Shaking- and reverse air |

350-450 |

417-667 |

250-400 |

|

Low pressure cleaning |

400-500 |

250-583 |

150-35 |

|

Pulse Jet |

500-650 |

83-250 |

90-150 |

Filter bags material character

|

Resistance of synthetic fiber to the influence of chemicals and to temperatures |

|||||||||

|

Filter type |

Continuous temperature |

Peak temperature |

Resistance to hydrolysis |

Resistance to acids |

Resiatance to alkalis |

Resistance to oxidation |

Ph value |

Application |

Remark |

|

Pp |

90℃ |

95℃ |

Excellent |

Excellent |

Excellent |

Restricted |

1-14 |

Applicable to food, flour, sugar, fertilizer, electroplating and pesticide industries |

Restricted resistance to oxidation, but excellent resistance to hydrolysis |

|

Co-acrylic |

115℃ |

120℃ |

Good |

Moderate |

Moderate |

Good |

6-13 |

Applicable to dergent industry and coal powder collection |

Good resistance to hydrolysis |

|

Co-acrylic |

125℃ |

140℃ |

Good |

Good |

Moderate |

Good |

3-11 |

Applicable to detergent, waste incineration, asphalt, spray dryer, coal mill and power plant industries |

Good resistance to hydrolysis |

|

Polyester |

150℃ |

150℃ |

Restricted |

Moderate |

Restricted |

Good |

4-12 |

Applicable to mine, limestone, cement, iron and steel induestries,alumina delivery, electrolytic aluminium, non-ferrous metal production, wood processing, food processing and pharmacy industry. |

Good resistacne to oxidation, while limited resistance to acids and alkalis. Serive life will be affected by water content under high temperature |

|

Pps |

190℃ |

200℃ |

Excellent |

Excellent |

Excellent |

Moderate |

1-14 |

Applicable to the working conditions with low oxidation gas from coal-fired boiler, waste incineration, metal smelting and chemical industries |

Moderate resistance to oxidation, but excellebnt resistance to acids and alkalis. |

|

M-aramide |

200℃ |

220℃ |

Moderate |

Moderate |

Moderate |

Moderate |

5-9 |

Licable tp asphalt, non-ferrous metal production, ceramic, glass industries, kilin in cement factories and blast furnace in steel factory |

Moderate resistance to oxidation. Characteristics will be influenced by water content under high temperature. |

|

Polyimide |

240℃ |

260℃ |

Good |

Moderate |

Moderate |

Good |

3-13 |

Applicable to the working condition with corrosive gas, such as chemical, metal smelting, waste incineration industries, cement kiln and coal-fired boiler |

Excellent resistance to high peak temperature |

|

Ptee |

250℃ |

280℃ |

Excellent |

Excellent |

Excellent |

Excellent |

1-14 |

Applicable to the working condition with high corrosive gas and high temperature, such as chemical industry, coal-fired boiler, waste incineration industry and non-ferrous metal production |

Excellent resistance to all chemical influences. |

Specification

|

Material |

100% PTFE fiber |

|

|

Weight (g/m2) |

700 |

|

|

Thickness (mm) |

1.1 |

|

|

Blasting strength ( N/cm2 ) |

>300 |

|

|

Air permeability (m3/m2/min) |

10-12 |

|

|

Breaking strength (N/520cm) |

warp |

>700 |

|

weft |

>800 |

|

|

Breaking elongation (%) |

warp |

<10% |

|

weft |

<10% |

|

|

Continuous operating temperature (℃) |

≤250 |

|

|

Instantaneous temperature (℃) |

280 |

|

|

Finish Treatment |

Heat setting |

|

|

Diameter (mm) |

Length (mm) |

Weight (g/㎡) |

|

120, 130, 133, 155, 180, 200, 250, 292, 300 |

1000, 1500, 2000, 2400, 25000, 2480, 2800, 3000, 3200, 3600, 4000, 4400, 5000, 6000, 8000 |

600, 650, 700, 800 |

|

Most commonly used dimensions |

133mm*1500mm, 133mm*2000mm, 133mm*2500mm |

|

|

Most commonly used weight |

700g |

|

|

We can customize diameter, length, and weight for you |

||

Application

PTFE filter bags are widely used to purify industrial dust with high temperature, high humidity and high viscosity, or industrial dust containing acidic and corrosive chemical gases. PTFE filter bag has a very important use in high-temperature flue gas filtration industry, with broad application prospects, mainly for the following aspects:

(1) Garbage incinerator, etc. It can purify flue gas with high humidity, high temperature, and high water content, strong chemical corrosively and high viscosity dust. The treatment of PTFE filter bags, especially the treatment of waste medical supplies and household garbage, can solve the problems of high-temperature combustion bags, high viscosity dust paste bags, and chemical gas corrosion bags and so on.

(2) Purification of industrial smoke and dust in power plant boilers burning high sulfur coal with acid, alkali and corrosive chemical gases; PTFE filter bag mainly has the advantages of non-sticking bag, easy dust removal, small running resistance of equipment, long service life, etc.

(3) Flue Gas Purification of Blast Furnace Gas in Iron and Steel Smelter. PTFE filter bag is mainly used to solve the corrosion problem caused by chemical gases such as high temperature, high humidity, paste bags below dew point and high-temperature sulfur.

Company Information

With the first-class level equipment, advanced R&D ability, high quality large dust collector bags, SHANGHAI SFFILTECH CO., LTD plays a big role in this industry. Our factory features a good location, which provides easy access to customers, workers, materials, and so on. This will maximize opportunity while minimizing our costs and risks. The aim of SHANGHAI SFFILTECH CO., LTD is taking the road of international brand. Inquire now!

Sincerely welcome customers who have needs to contact us for negotiation. I hope we can work together to create a brilliant future.