Crafting Your Own Custom Filter Cloth: A Detailed Guide

Filter cloths are essential tools in various industries, including water treatment, air filtration, and industrial hygiene. They serve as a barrier to remove impurities, contaminants, or particles from a fluid or gas. While filter cloths are readily available in stores, creating your own custom filter cloth allows for greater customization, cost savings, and efficiency tailored to specific needs. This guide will walk you through every step of the process, from selecting the right materials to designing and manufacturing your own filter cloth.

Understanding Filter Cloths

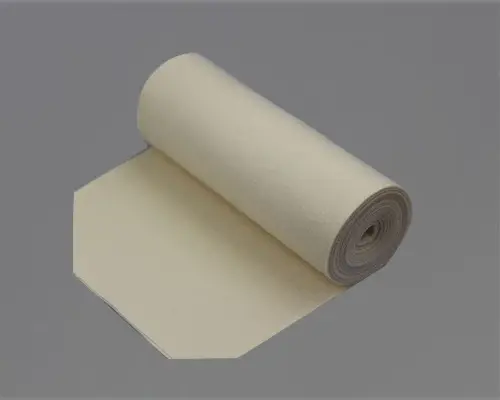

Filter cloths, also known as media, are porous materials designed to capture particles from a fluid or gas. They come in various sizes, shapes, and materials, each suitable for different applications. Whether you're a homeowner looking to purify water or a business owner seeking to improve air quality in your facility, a custom filter cloth can provide the precision and efficiency you need.

Crafting your own filter cloth is an affordable way to create a solution that meets your specific requirements. Instead of relying on off-the-shelf products, you can design a filter cloth that is optimized for your particular application. This guide will provide you with the knowledge and tools to create a high-quality, custom filter cloth.

Why Craft Your Own Filter Cloth?

Benefits of Custom Filter Cloth

Custom filter cloths offer several advantages over commercially available options. Here are some key benefits:

- Cost Savings: Manufacturing your own filter cloth allows you to save money by eliminating the need to purchase multiple filter cloths for different applications.

- Precision and Customization: Custom filter cloths can be designed to meet specific size, shape, and material requirements. This makes them ideal for industries where precise filtration is critical, such as pharmaceuticals, food processing, and water treatment.

- Efficiency: A custom filter cloth can be tailored to the unique needs of your application, ensuring maximum efficiency and effectiveness in capturing particles.

- Versatility: Custom filter cloths can be used in a wide range of applications, from home water filtration systems to industrial air filtration systems.

- Sustainability: By reducing the number of filter cloths you need, you can help minimize waste and reduce your environmental footprint.

How DIY Methods Can Cater to Specific Needs

While commercial filter cloths are readily available, they may not always meet the specific needs of your application. For example, a business owner may need a filter cloth with a specific pore size or thickness to handle a particular volume of air or water. Similarly, a homeowner may need a filter cloth designed to handle a specific flow rate of water.

By crafting your own custom filter cloth, you can ensure that your solution is tailored to your needs, providing the precision, efficiency, and durability required for your application.

Selecting the Right Materials for Your Filter Cloth

The choice of material is one of the most critical factors in determining the performance of your custom filter cloth. Different materials have different properties, such as pore size, thickness, and hydrophobicity, which affect their filtration efficiency.

Common Materials for Filter Cloth

- Cotton: Cotton is a popular choice for filter cloth due to its low cost and natural fibers. It is breathable and has a relatively large pore size, making it suitable for general-purpose applications.

- Polyester: Polyester is a synthetic material that is durable and has a high strength-to-weight ratio. It is commonly used in filter cloth applications where durability and resistance to wear and tear are important.

- Polypropylene: Polypropylene is another synthetic material that is strong and durable. It is often used in applications where a fine mesh or high pore density is required.

- Nylon: Nylon is a synthetic material that is lightweight and has a high strength-to-weight ratio. It is commonly used in filter cloth applications where durability and resistance to chemicals are important.

- Textron: Textron is a synthetic material that is similar to polyester but has a finer mesh, making it more suitable for fine particle filtration.

Each of these materials has its own advantages and disadvantages, and the choice of material depends on the specific requirements of your application. For example, if you need a filter cloth that is highly durable and resistant to wear and tear, you may opt for polyester or polypropylene. If you need a filter cloth that is lightweight and has a high pore density, you may choose nylon or cotton.

Designing Your Custom Filter Cloth

Key Considerations in Design

When designing your custom filter cloth, there are several key considerations to keep in mind:

- Material Type: The type of material you choose will determine the pore size and thickness of your filter cloth. You should select a material that is suitable for your application.

- Thread Count: The thread count refers to the number of threads per square inch in the filter cloth. A higher thread count results in a finer mesh, while a lower thread count results in a coarser mesh.

- Dimensions: The size of your filter cloth will depend on the flow rate of the fluid or gas you are filtering and the desired filtration efficiency. You should design your filter cloth to accommodate the specific dimensions of your application.

- Application: The application for which your filter cloth will be used will also influence the design. For example, filter cloths used in industrial applications may require additional features, such as reinforced edges or heat-resistant materials.

Step-by-Step Instructions for Designing Your Filter Cloth

- Determine the Material Type: Based on the requirements of your application, select the appropriate material for your filter cloth.

- Calculate the Required Thread Count: Use a thread count calculator or formula to determine the appropriate thread count for your filter cloth. A higher thread count will result in a finer mesh, while a lower thread count will result in a coarser mesh.

- Design the Filter Cloth Pattern: Draw a pattern for your filter cloth that includes the dimensions, thread count, and any additional features required for your application.

- Cut the Material: Using the pattern, cut the material to the required dimensions.

- Sew the Material: Stitch the material together using a sewing machine. Ensure to choose the appropriate stitching technique for your material to ensure durability.

- Finish the Edges: Hem or bind the edges of the filter cloth to ensure it is durable and protects the material from wear and tear.

By following these steps, you can design a custom filter cloth that is tailored to your specific needs.

Manufacturing Your Custom Filter Cloth

Basic Manufacturing Process

- Cutting the Material: The first step in manufacturing your custom filter cloth is cutting the material to the required dimensions. This can be done using scissors, a guillotine, or a fabric cutter.

- Sewing the Material: Once the material is cut, it is sewn together using a sewing machine. The type of stitch used will depend on the material and the desired durability of the filter cloth.

- Pressing the Edges: After sewing the material together, the edges are pressed to ensure they are straight and even.

- Finishing the Edges: The edges of the filter cloth can be finished using a variety of techniques, such as hemming, binding, or sewing with a bias tape to add durability.

- Machine Washing (Optional): If the filter cloth will be used in a washing machine, it should be washed separately in hot water to retain its integrity.

By following these steps, you can manufacture a high-quality, custom filter cloth that meets your specific needs.

Testing and Quality Assurance

Methods for Testing Filter Cloth Performance

- Filter Efficiency: Filter efficiency is a measure of how well the filter cloth captures particles from a fluid or gas. It is typically measured using a known flow rate of fluid or gas and a known concentration of particles in the fluid or gas.

- Resistance: Resistance is a measure of how easily the fluid or gas flows through the filter cloth. A higher resistance indicates a more efficient filter cloth.

- Durability: The durability of the filter cloth can be tested by exposing it to extreme temperatures, humidity, or chemicals and observing how long it remains effective.

Tips for Ensuring Quality

To ensure that your custom filter cloth meets industry standards and specifications, you should:

- Use high-quality materials and stitching techniques.

- Perform thorough testing to measure filter efficiency, resistance, and durability.

- Store the filter cloth in a clean, dry place to prevent degradation.

By following these tips, you can ensure that your custom filter cloth is of high quality and performs well in your application.

Maintenance and Longevity

Tips for Maintaining Your Custom Filter Cloth

- Cleaning: Cleaning the filter cloth regularly is essential to maintaining its performance. Depending on the application, you may need to clean the filter cloth in hot water or use a specialized cleaning solution.

- Storage: Store the filter cloth in a clean, dry place to prevent it from absorbing moisture or becoming contaminated.

- Replacing Worn-Out Parts: If the filter cloth is becoming worn out, it is important to replace it to ensure that it continues to perform well in your application.

By taking care of your custom filter cloth, you can ensure that it remains effective for as long as possible.

Case Study: Successful Custom Filter Cloth Projects

Real-World Examples

One business owner decided to implement custom filter cloths in their facility as part of a sustainability initiative. They installed custom filter cloths in their water treatment system and observed a significant reduction in water usage and a decrease in the need for additional purification equipment. This not only improved efficiency but also reduced costs and minimized waste.

Another homeowner installed custom filter cloths in their air filtration system and noticed a significant improvement in air quality. The custom filter cloths captured a higher percentage of particles from the air, leading to a reduction in the need for additional air purification equipment.

These case studies demonstrate the potential of custom filter cloths to improve efficiency, reduce costs, and enhance performance in a variety of applications.

Future Trends in Custom Filter Cloth Manufacturing

Emerging Technologies and Trends

- Nanofiltration: The use of nanofiltration technology is becoming increasingly popular in filter cloth manufacturing. Nanofiltration allows for the capture of particles that are too small to be captured by traditional filter cloths, making it ideal for applications where high precision is required.

- 3D Printing: 3D printing is revolutionizing the manufacturing of filter cloths by allowing for the creation of custom filter cloths with complex geometries and patterns. This technology is particularly useful for filter cloths that are tailored to specific applications, such as medical devices or industrial equipment.

- Smart Materials: The development of smart materials, such as those that respond to temperature or humidity changes, is also an emerging trend in filter cloth manufacturing. These materials can improve the performance and efficiency of filter cloths in real-time.

Exciting Possibilities Ahead

As technology continues to advance, there are exciting possibilities for the future of custom filter cloth manufacturing. From nanofiltration to 3D printing, these technologies have the potential to revolutionize the industry and create even more efficient and innovative filter cloth solutions.

Empowering Your Filtration Needs with Custom Filter Cloth

Summary of Key Points

Filter cloths are essential tools in many industries, and creating your own custom filter cloth allows you to tailor a solution to your specific needs. By selecting the right materials, designing and manufacturing your filter cloth carefully, and testing it thoroughly, you can create a high-quality, custom filter cloth that meets your performance requirements.

Whether you're a homeowner looking to improve air quality or a business owner seeking to enhance efficiency, custom filter cloth is a powerful tool that can make a significant difference. By investing time and effort into creating a custom filter cloth, you can empower your filtration needs and achieve greater success in your application.