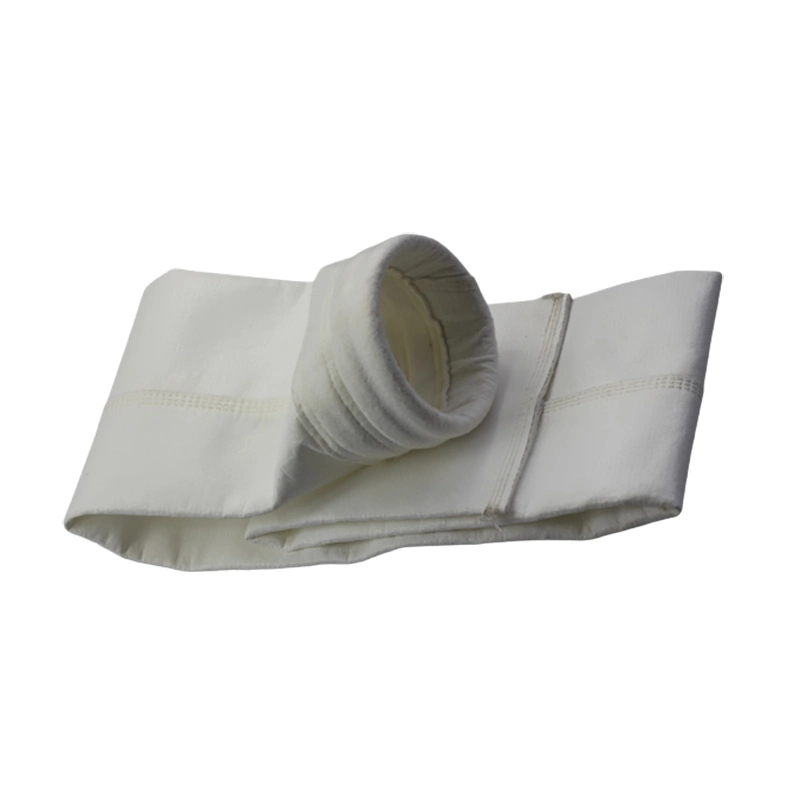

SFFILTECH food grade pp filter bag for food flour

Product Description

PP needle punched felt filter bag, made from PP needle punched felt produced by needle punching method. PP fibers are produced using different production equipment and manufacturing processes based on the characteristics of working conditions and usage requirements. After special hydrophobic treatment, PP needle felt with high filtration performance is produced through singeing, heat setting, and rolling. Then, sew a traditional PP filter bag with PP needle felt.

SFFILTECH food grade pp filter bag for food flour

Discover the versatility of Polypropylene (PP) filter bags, meticulously designed for industrial excellence. From the resilient PP fiber filter bags, providing effective chemical resistance, to high-temperature PP filtration solutions, we offer a comprehensive range. Our commitment extends to custom PP filter bags tailored to unique requirements, ensuring precision in dust collection and membrane applications. Embrace the superior performance of anti-static PP bags, enhancing safety in various industrial settings. With a focus on quality and adaptability, our PP filter bags stand as reliable solutions for a spectrum of industrial filtration needs.

Two factors effect the choice of filter bags

Dust Separation Procedure

Different dust separation procedures require different weights and air permeability values for filter media.

Rules:

- The more effective the cleaning process, the more compact and heavier the filter medium can be.

- The higher the emission control standards, the heavier the filter medium should be.

Tops: If these factors are well considered in advance, running cost like electricity for the fan or pressured-air for the cleaning pulses can be saved later on in a great amount.

|

Dust Separation Procedure |

(g/m2) |

Air Permeability |

|

|

mm/s @200Pa |

l/(dm²min) @200Pa |

||

|

Intermittent Shaking |

300-350 |

667-1000 |

400-600 |

|

Shaking- and reverse air |

350-450 |

417-667 |

250-400 |

|

Low pressure cleaning |

400-500 |

250-583 |

150-35 |

|

Pulse Jet |

500-650 |

83-250 |

90-150 |

Filter bags material character

|

Resistance of synthetic fiber to the influence of chemicals and to temperatures |

|||||||||

|

Filter type |

Continuous temperature |

Peak temperature |

Resistance to hydrolysis |

Resistance to acids |

Resiatance to alkalis |

Resistance to oxidation |

Ph value |

Application |

Remark |

|

Pp |

90℃ |

95℃ |

Excellent |

Excellent |

Excellent |

Restricted |

1-14 |

Applicable to food, flour, sugar, fertilizer, electroplating and pesticide industries |

Restricted resistance to oxidation, but excellent resistance to hydrolysis |

|

Co-acrylic |

115℃ |

120℃ |

Good |

Moderate |

Moderate |

Good |

6-13 |

Applicable to dergent industry and coal powder collection |

Good resistance to hydrolysis |

|

Co-acrylic |

125℃ |

140℃ |

Good |

Good |

Moderate |

Good |

3-11 |

Applicable to detergent, waste incineration, asphalt, spray dryer, coal mill and power plant industries |

Good resistance to hydrolysis |

|

Polyester |

150℃ |

150℃ |

Restricted |

Moderate |

Restricted |

Good |

4-12 |

Applicable to mine, limestone, cement, iron and steel induestries,alumina delivery, electrolytic aluminium, non-ferrous metal production, wood processing, food processing and pharmacy industry. |

Good resistacne to oxidation, while limited resistance to acids and alkalis. Serive life will be affected by water content under high temperature |

|

Pps |

190℃ |

200℃ |

Excellent |

Excellent |

Excellent |

Moderate |

1-14 |

Applicable to the working conditions with low oxidation gas from coal-fired boiler, waste incineration, metal smelting and chemical industries |

Moderate resistance to oxidation, but excellebnt resistance to acids and alkalis. |

|

M-aramide |

200℃ |

220℃ |

Moderate |

Moderate |

Moderate |

Moderate |

5-9 |

Licable tp asphalt, non-ferrous metal production, ceramic, glass industries, kilin in cement factories and blast furnace in steel factory |

Moderate resistance to oxidation. Characteristics will be influenced by water content under high temperature. |

|

Polyimide |

240℃ |

260℃ |

Good |

Moderate |

Moderate |

Good |

3-13 |

Applicable to the working condition with corrosive gas, such as chemical, metal smelting, waste incineration industries, cement kiln and coal-fired boiler |

Excellent resistance to high peak temperature |

|

Ptee |

250℃ |

280℃ |

Excellent |

Excellent |

Excellent |

Excellent |

1-14 |

Applicable to the working condition with high corrosive gas and high temperature, such as chemical industry, coal-fired boiler, waste incineration industry and non-ferrous metal production |

Excellent resistance to all chemical influences. |

Specification

|

Construction |

Needle punch felt |

|

Fiber Composition |

100% PP |

|

Scrim Composition |

100%PP |

|

Felt Area Weight |

450g/m2 |

|

Thickness |

1.7mm |

|

Density |

0.26g/cm3 |

|

Mean Air Permeability |

140L/dm2.min |

|

Breaking Strength-MD(warp) |

≥1200 N/5cm |

|

Breaking Strength-CMD(weft) |

≥1200 N/5cm |

|

Breaking Elongation(200 N/5cm)-MD(warp) |

<5% |

|

Breaking Elongation( 200N/5cm)-CMD(weft) |

<5% |

|

Dry Shrinkage (150℃, 90min) |

1% |

|

Blasting strength |

>300 N/cm2 |

|

Operating Temperatures |

<90℃ |

|

Continuous |

90℃ |

|

Recommended Maximum Surge |

100℃ |

|

Finish |

Heat set, singed, calendared W/O Repellent |

|

Diameter (mm) |

Length (mm) |

Weight (g/㎡) |

|

120, 130, 133, 155, 180, 200, 250, 292, 300 |

1000, 1500, 2000, 2400, 25000, 2480, 2800, 3000, 3200, 3600, 4000, 4400, 5000, 6000, 8000 |

300, 350, 400, 450, 500, 550, 600 |

|

Most commonly used dimensions |

133mm*1500mm, 133mm*2000mm, 133mm*2500mm |

|

|

Most commonly used weight |

400g, 450g, 500g |

|

|

We can customize diameter, length, and weight for you |

||

Application

In terms of liquid filtration, polypropylene needle felt filter bags are usually used with plate frame filter press, vacuum suction filter, bag filter, centrifugal filter and other liquid-solid separation equipment. With good dimensional stability, high strength, long service life and other characteristics, it also has small resistance, easy cleaning and other unique advantages. In mineral processing, coal preparation, petroleum, chemical and other industries, where it is necessary to filter small particles and ensure filtering, polypropylene needle punched felt has far superior performance than traditional woven filter materials.

Polypropylene needle punched filter felt is mainly used in the liquid-solid separation fields of metallurgy, mining, petroleum, chemical industry, chemical fiber, medicine, food and other industries.